The Wholesaler’s Reality: You Aren’t Buying Film, You’re Buying Predictability

In the B2B wholesale supply chain, the most expensive line item isn’t the raw material—it’s uncertainty. When building a brand or establishing a regional distribution network, your reputation hinges on consistency.

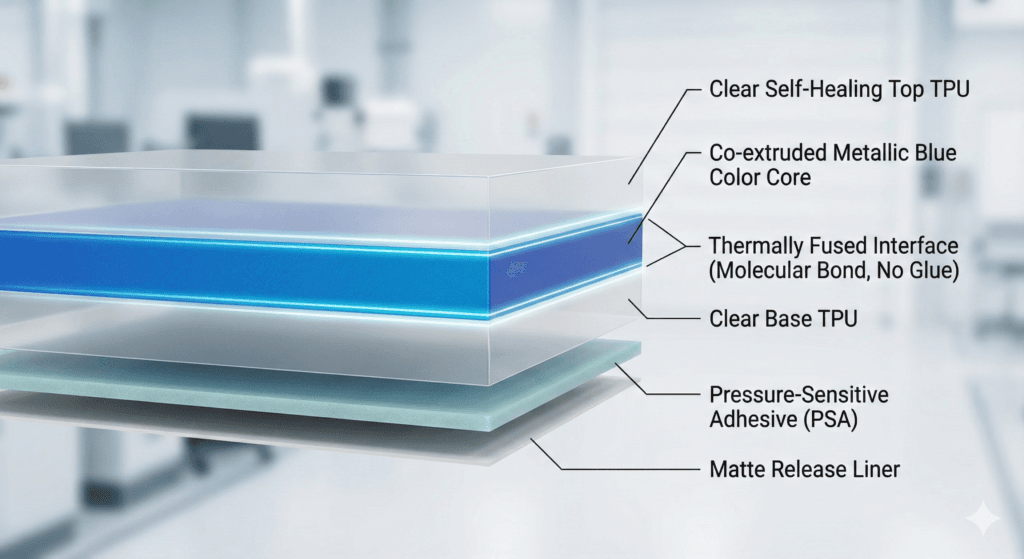

Batch fluctuation (where roll A feels different from roll B) and structural failure (delamination, fading, or adhesive residue) are rarely installation errors. They are manufacturing characteristics defined by how the film was constructed. To mitigate these risks, distributors need to look beyond the datasheet and understand the membrane structure: How are the layers bonded? How are pigments distributed? Is the film co-extruded or laminated?

This guide translates technical manufacturing processes into actionable sourcing logic.

1. The Core Principle: Why Co-Extrusion Outperforms Lamination

Defining the Difference

It is a common misconception that “more layers” simply means a thicker film. The critical factor is the interface stability between those layers.

According to technical documentation from Kraiburg TPE, the co-extrusion process involves joining multiple materials in a molten state. While the materials come from separate barrels and remain distinct layers, they are bonded thermally during the extrusion process itself. They do not mix, but they bond at a molecular level before cooling [1].

For a PPF wholesaler, this distinction is vital. If a film relies on a “post-lamination” process (gluing layers together after they are formed), the interface becomes a weak point. Under long-term heat, UV exposure, and mechanical stretching, that glue line is often the first to fail, leading to delamination. Co-extrusion creates a monolithic structure that is inherently more stable and suitable for high-volume, consistent production.

The Science of “Microlayers”

Advanced manufacturing now utilizes microlayer co-extrusion. While standard co-extrusion might have two or three layers, microlayer technology can create dozens of alternating layers within the same thickness.

A study published by the Royal Society of Chemistry (RSC) highlights a mechanism critical for film performance. The research found that microlayer co-extrusion significantly improves the dispersion and orientation of additives within a TPU matrix. In their testing, fillers were not just mixed in; the shear forces of the co-extrusion process aligned them into a highly ordered structure [2].

Why this matters for PPF: The logic applies directly to how UV stabilizers and pigments behave in Paint Protection Film. Better dispersion and alignment mean:

- Fewer Weak Spots: Additives are spread evenly, reducing “hot spots” where failure begins.

- Mechanical Consistency: The RSC study noted that microlayer samples showed a 123% increase in tensile strength and an 85% increase in elongation at break compared to traditional blending [2]. For a distributor, this translates to consistent installation “feel” and less tearing during stretch.

2. Colored TPU: Process Routes Define the Risk Profile

The market for Colored PPF is growing, but it is also the source of the highest warranty claims. KPAL Automotive outlines several manufacturing routes for colored films. Understanding which route your factory uses is the best way to predict potential failure [3].

Route A: Coating (TPU + PU Color Layer)

- The Process: A clear TPU base is coated with a colored Polyurethane layer, followed by adhesive.

- The Risk: This relies heavily on the chemical bond between the coating and the TPU. If this bond is weak, the film suffers from poor weather resistance and potential delamination. High humidity and UV heat can accelerate the degradation of the PU coating, leading to fading or gloss loss.

- Verdict: High risk for long-term applications.

Route B: Surface Coloring (Color Layer + TPU)

- The Process: The color layer is on top, often protected by a clear coat.

- The Risk: While cost-effective, this method exposes the color layer to the harshest elements. Stretching the film during installation can thin the color layer unevenly, causing “whitening” or color shifts. Furthermore, solvents and environmental contaminants attack the color directly once the topcoat wears down.

- Verdict: Suitable for budget lines, but prone to installation complaints.

Route C: The “Sandwich” Structure (TPU + Color + TPU)

- The Process: A multi-layer co-extrusion where the color pigment is encapsulated between clear TPU layers.

- The Advantage: This achieves the “original paint” look with high gloss and depth. Because the color is protected inside the structure, it is shielded from solvents and abrasion.

- The Risk: This is the most technically difficult method. It requires precise control to prevent “color leakage” or layer separation during the melt phase.

- Verdict: The premium choice. If the manufacturer controls the co-extrusion well, this offers the best longevity.

3. Commercial Implications: Turning Technology into Profit

Understanding these structures allows you to make smarter business decisions.

Lower Warranty Costs By prioritizing co-extruded structures over laminated ones, you eliminate the “glue failure” variable. Delamination and adhesive residue are often symptoms of poor interface bonding. A thermally bonded co-extruded film is structurally one piece, drastically reducing these specific warranty claims.

Defensible Pricing When a dealer asks why your film costs more than a competitor’s, you have a technical narrative. You aren’t just selling “shiny plastic”; you are selling a microlayer co-extruded structure that ensures better additive dispersion (UV protection) and mechanical strength [2].

Clear SKU Segmentation Use manufacturing methods to define your product tiers:

- Entry Level: Laminated or Surface-Colored films (Short-term aesthetic change).

- Flagship: Co-extruded “Sandwich” films (Long-term protection and paint-like finish).

4. The Wholesaler’s Vetting Checklist

When auditing a factory or testing new samples, use these questions to uncover the true capabilities of the supplier:

On Structure & Process:

- “For your colored PPF, is the color layer co-extruded as a central core (Sandwich), or is it a surface coating?”

- “If using the Sandwich method, how do you manage interlayer adhesion and color leakage?” [3]

- “Is the base film produced via single-layer extrusion or multi-layer co-extrusion?”

On Validation:

- “How do you test for color shift under 30% stretch?” (Critical for colored PPF).

- “Do you have comparative data on solvent resistance for your Coated vs. Co-extruded colored films?”

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between Co-extruded and Laminated PPF structures? A: The difference lies in the bonding interface. Co-extrusion fuses materials while they are in a molten state, creating a thermally bonded, monolithic structure. Laminated or coated structures rely on adhesives or chemical bonds to join layers that have already solidified. Consequently, laminated films generally face higher risks of delamination and aging because the bonding interface acts as a physical weak point [1].

Q2: Why is Colored TPU PPF more prone to fading or surface cracking than clear film? A: This is often a symptom of the manufacturing route. If a factory uses the “Surface Coating” method (Route B), the color layer is exposed. Stretching the film during installation can thin the pigment unevenly (whitening), and the lack of a thick outer TPU layer leaves the color vulnerable to solvents and UV degradation. Co-extruded films protect the pigment by embedding it within the TPU matrix [3].

Q3: Is the “Sandwich” structure (TPU+Color+TPU) always the best choice for colored film? A: It is the “highest ceiling” option for premium brands because it offers the best depth, gloss, and self-healing properties. However, it is not the easiest to produce. It requires high-precision machinery to prevent “color leakage” or internal layer separation. It is the superior choice only if the manufacturer has a proven quality control process for co-extrusion [3].

Q4: How does “Microlayer” technology actually improve film performance? A: It is not just about stacking more layers; it is about structural control. Research shows that the microlayer co-extrusion process helps align the internal structure of additives and fillers (orientation). This alignment results in significantly higher tensile strength and better elongation compared to standard blended materials, ensuring the film behaves consistently from roll to roll [2].

References

- Kraiburg TPE. The Co-extrusion Process: Combining Materials Efficiently. https://www.kraiburg-tpe.com/en/co-extrusion-process

- Royal Society of Chemistry. EG/TPU composites with enhanced flame retardancy and mechanical properties prepared by microlayer coextrusion technology. https://pubs.rsc.org/en/content/articlehtml/2019/ra/c9ra03653a

- KPAL Automotive. Pros and Cons of Color TPU PPF Manufacturing Methods. https://www.kpalautomotive.com/Exhibition-news/pros-and-cons-of-color-tpu-ppf-manufacturing-methods